Cross-linked polyethene (PEX) pipes are popular in modern plumbing systems. They offer homeowners and contractors a versatile and durable solution.

PEX comes in two types: PEX A and PEX B. Understanding their differences is key for your next plumbing project.

We’ll explore PEX A and PEX B’s manufacturing processes and performance features. We’ll also look at installation factors and cost considerations.

This guide will help you choose the best PEX type. It’s useful for both new construction and renovation projects.

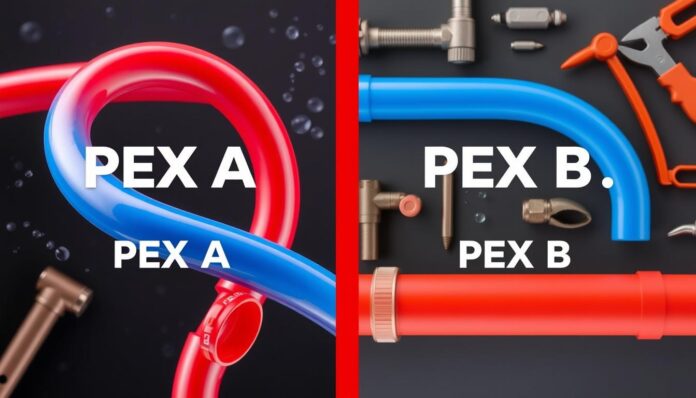

A split image showcasing PEX A and PEX B plumbing pipes, highlighting their distinct characteristics. On one side, PEX A pipes have a smooth, flexible design in vibrant red and blue, seamlessly bending around corners. Conversely, PEX B pipes with a more rigid structure in the same colours display their slightly thicker walls. Include background elements like water droplets and tools commonly used in plumbing, creating an engaging contrast between the two types of pipes.

Understanding PEX: A Quick Overview

PEX is a flexible, durable piping solution. It has changed how we distribute water in our homes.

PEX stands for cross-linked polyethylene. It’s more substantial and more flexible than copper or PVC pipes.

Cross-linking makes PEX strong and flexible. This process also helps it resist corrosion and chemicals.

PEX can handle high heat and pressure. This makes it great for hot and cold water systems.

PEX is easy to install. It can fit into tight spaces and complex piping runs.

PEX resists freezing better than other pipes. It can expand and contract with temperature changes.

This quality makes PEX popular in cold climates. It reduces the risk of burst pipes and water damage.

PEX is helpful for more than just water pipes. It’s often used in radiant floor heating systems.

PEX can be routed through walls, floors, and ceilings, making it valuable for construction and renovation projects.

The Basics of PEX A and PEX B

PEX-A and PEX-B are popular plumbing pipe options. Both are cross-linked polyethene materials with different manufacturing processes.

PEX-A is made using high heat and pressure. This results in a flexible and strong pipe.

PEX-A is more durable and performs better. It resists chemical breakdowns well.

PEX-B uses silane cross-linking agents in its production. This makes it less flexible and long-lasting than PEX-A.

PEX-B is still a good choice for many plumbing jobs. It’s reliable and widely used.

Choose between PEX-A and PEX-B based on your specific needs. Consider the use, installation, and local building rules.

Comparing Manufacturing Processes

PEX plumbing pipes are made using different methods. These methods affect the pipes’ final properties.

PEX A is made using the peroxide method. PEX B uses the silane method.

The peroxide method adds organic peroxide compounds during extrusion. This creates a highly cross-linked structure.

PEX A pipes are more rigid and durable. The silane method for PEX B uses different compounds.

Silane reacts with moisture to form cross-links. This makes PEX B pipes more flexible and pliable.

PEX A works well in high-temperature and high-pressure settings. PEX B is great for easy installation and flexibility.

Choose the pipe that fits your plumbing needs best. Consider the specific requirements of your project.

Key Differences Between PEX A and PEX B

PEX A and PEX B have unique traits that affect their use. PEX A is more flexible and durable due to its manufacturing process.

This allows PEX A pipes to fit into tight spaces easily and handle complex plumbing layouts without losing strength.

PEX B pipes are less flexible but resist thermal memory better. This means they keep their shape after bending.

PEX B is easier to install. The pipes are less likely to kink during setup.

The making of these pipes causes their differences. PEX A uses the Engel or peroxide method.

This gives PEX more flexibility and kink resistance. PEX B uses the silane method.

This gives PEX B better thermal memory performance. Choosing between PEX A and B depends on your needs.

Consider flexibility, thermal memory, and kink resistance. This will help you choose the best option for your project.

Performance Characteristics

PEX A and PEX B pipes have impressive heat resistance. PEX A can operate at temperatures up to 200°F (93°C) without damage.

PEX B typically has a higher burst pressure rating than PEX A, making it more durable for high-pressure applications.

Both PEX A and PEX B show excellent freeze resistance. They can expand and contract with temperature changes.

PEX A and PEX B maintain their performance over time. This makes them popular for homes and businesses.

Installation Factors

PEX A and PEX B installations differ in methods and tools. Their choice impacts the overall plumbing process.

PEX A uses expansion fittings with an expansion tool. This method ensures a secure, easily disassembled connection.

PEX B uses crimp fittings with a metal ring. Crimping can be done with a hand or power tool.

Expansion fittings need more skill but offer adjustable connections. Crimp fittings are faster and simpler to install.

This is a close-up view of various types of expansion fittings for PEX piping, showcasing their colourful design and intricate details arranged on a neutral background. Emphasize the different shapes and sizes, highlighting the textures and materials used in plumbing applications. Incorporate a subtle sheen to represent the metallic components and a slight reflection to convey depth.

When choosing PEX types, consider project needs and the plumber’s skills. Understanding these methods helps create a lasting plumbing system.

Cost Considerations

PEX A and PEX B have different plumbing costs. Understanding their prices can help you choose wisely.

Due to its advanced manufacturing, PEX A costs more than PEX B. However, the price difference is often small compared to the long-term benefits.

Installation costs for both types are similar. PEX systems are faster to install than copper or CPVC pipes.

PEX’s flexibility means fewer connections. This reduces installation time and expenses even more.

PEX pipes offer long-term savings through durability and efficiency. They resist corrosion, freezing, and scaling better than other pipes.

This durability leads to fewer repairs and replacements, saving money on maintenance and utility bills.

When choosing between PEX A and PEX B, consider all factors. Consider material costs, installation, and potential savings.

Applications and Use Cases

PEX pipes offer many uses in homes and businesses. They’re great for house water supply lines, giving a flexible and reliable option.

PEX pipes work well in commercial settings, too. They’re perfect for radiant heating systems and easy to install in tight spaces.

PEX shines in radiant heating systems. Its flexibility allows for efficient and energy-saving heating in homes and businesses.

PEX pipes are useful for more than just home plumbing. They’re a top choice for many plumbing needs in various settings.

Environmental Impact

Eco-friendly plumbing is gaining importance. PEX A and PEX B pipes are more sustainable than traditional metal pipes.

PEX A’s cross-linked structure makes it highly recyclable. It can be made into new products with little waste.

PEX B is also recyclable. However, its recycling process may be more complex.

PEX A production uses less energy than PEX B. This gives PEX A a lower carbon footprint.

Both PEX types are better for the environment than traditional materials. They’re recyclable and use less energy to produce.

These pipes appeal to those who want to reduce their impact. They’re great for eco-conscious homeowners and contractors.

Common Myths Debunked

Many myths surround PEX safety, durability, and performance in plumbing. Let’s look at some common misconceptions and debunk them with facts.

Some believe PEX pipes are not durable and can easily burst. PEX is highly resistant to chemicals, corrosion, and extreme temperatures.

PEX pipes are designed to withstand high pressures and are less prone to leaks than copper or steel pipes.

There’s a myth that PEX pipes promote bacterial growth. Studies show PEX doesn’t support microbial growth, ensuring safe drinking water.

PEX has a smooth inner surface. This makes it less likely to accumulate buildup or sediment.

Some think UV light affects PEX pipes. PEX can be installed indoors and outdoors without performance issues.

Experts and researchers have debunked durability myths about PEX. It’s proven to be a reliable plumbing solution.

User Experiences and Reviews

Customer reviews are key for plumbing pipes. PEX A and PEX B both get praise from users and pros.

Homeowners love PEX A’s easy setup and toughness. It’s flexible and resists freezing and rust.

Plumbers like PEX A because of its quick installation. It lasts long, even in tough spots.

PEX B also gets good marks from users. Contractors like its low cost for budget projects.

Homeowners praise PEX B’s flexibility and easy installation. Plumbers find it simple to work with.

Both PEX A and B show excellent real-world performance. Your choice depends on your needs and likes.

Making the Right Choice

PEX A and PEX B pipes offer unique benefits for plumbing projects. Your project needs and likes will guide your choice.

PEX A is excellent for radiant heating and hot water systems. It bends easily and handles high temps well.

PEX B works best for cold water lines. It’s often cheaper than PEX A.

Both PEX types are easy to install. But they use different methods.

Ask a pro plumber for help choosing the right PEX. They can guide you on fittings, tools, and methods.

FAQ

What is the difference between PEX A and PEX B?

PEX A and PEX B differ in their manufacturing process. PEX A uses the peroxide method, while PEX B uses the silane method.

This leads to unique molecular structures and performance traits.

Which type of PEX is more flexible?

PEX A is more flexible than PEX B. Its manufacturing method creates a stretchable structure for easier bending.

How do the temperature and pressure ratings compare between PEX A and PEX B?

PEX A has higher temperature and pressure ratings. This is due to its stronger molecular bonds.

It can handle more challenging conditions, making it ideal for demanding uses.

Which type of PEX is more resistant to kinking?

PEX B resists kinking better due to higher thermal memory. Its structure is less prone to permanent bending or twisting.

How do the installation methods differ between PEX A and PEX B?

PEX A uses expansion fittings with an expansion tool. PEX B uses crimp fittings with a unique crimping tool.

Which type of PEX is more cost-effective?

PEX B is often cheaper upfront. Its materials and tools cost less.

However, PEX A may save money in the long term due to better performance.

What are the typical applications for PEX A and PEX B?

Both are used in plumbing and heating systems. PEX A suits demanding jobs due to higher ratings.

PEX B works well in tight spaces thanks to its kink resistance.

Are PEX A and PEX B environmentally friendly?

Yes, both PEX types are eco-friendly. They’re recyclable and have a low carbon footprint.

Their manufacturing processes also have minimal environmental impact.

You can also read more : How Long Does It Take to Become a Surgical Tech